Automatic Level Control

Maintains optimal adhesive levels with a high-temp sensor and micro-charges, preventing overfill or dry runs.

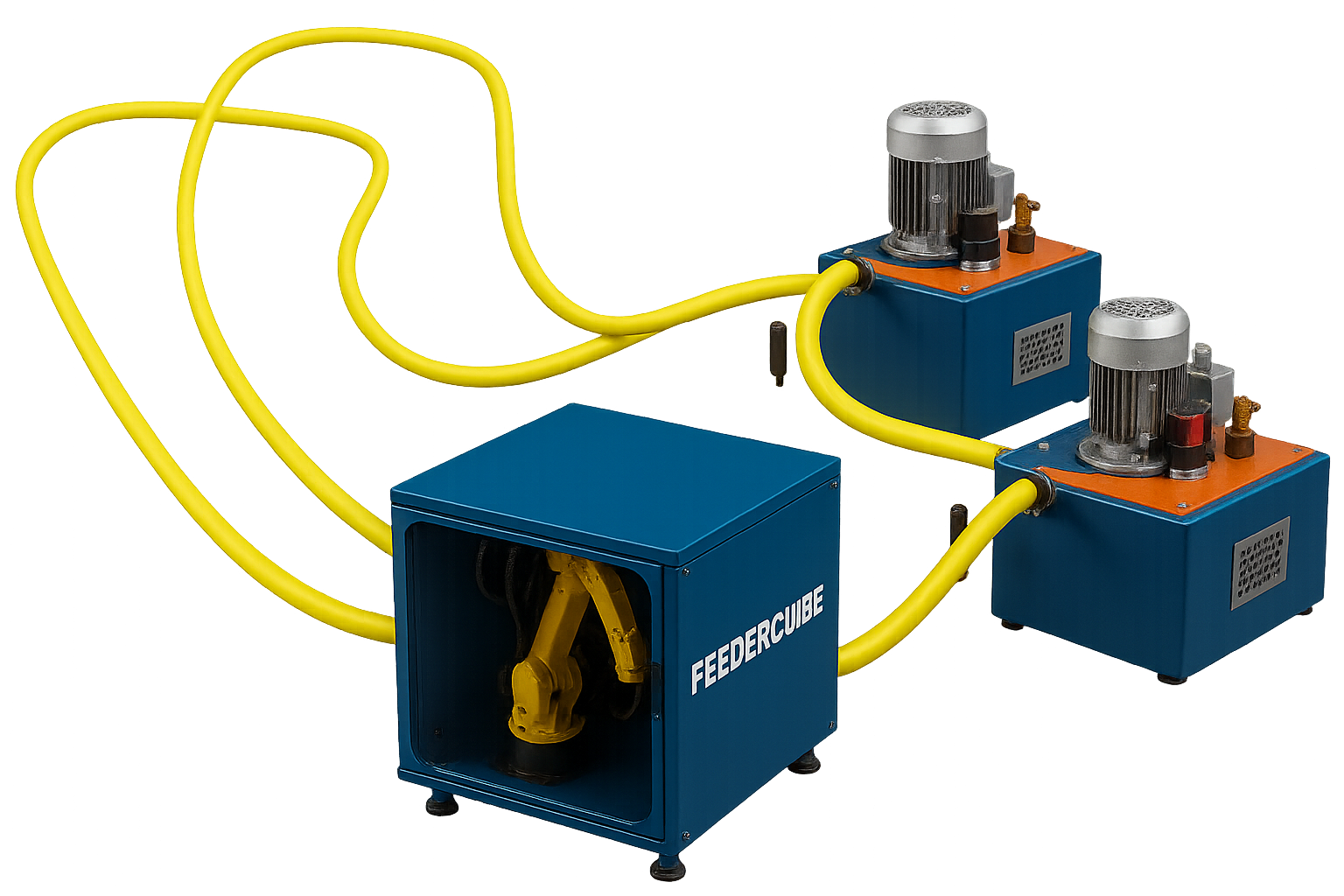

Automatic hot-melt feeder for packaging systems, maintaining optimal tank levels and minimizing maintenance in Merano, Italy.

Maintains optimal adhesive levels with a high-temp sensor and micro-charges, preventing overfill or dry runs.

Dust-filtered lid, insulated cover, and GMP-style design ensure operator safety and a clean workspace.

Reduces crystallization, minimizes maintenance, and eliminates manual loading stops for cost savings.

Expert installation, maintenance, and training for MY FEEDER CUBE and packaging systems.

Our Merano-based team provides professional field service for MY FEEDER CUBE, ensuring seamless installation, regular maintenance, and operator training. We minimize downtime and optimize performance for your packaging systems.

Request ServiceGet in touch for more details or a quote for MY FEEDER CUBE.

J. Kravogl Str. 28

Meran Sinich (BZ), 39012, Italy